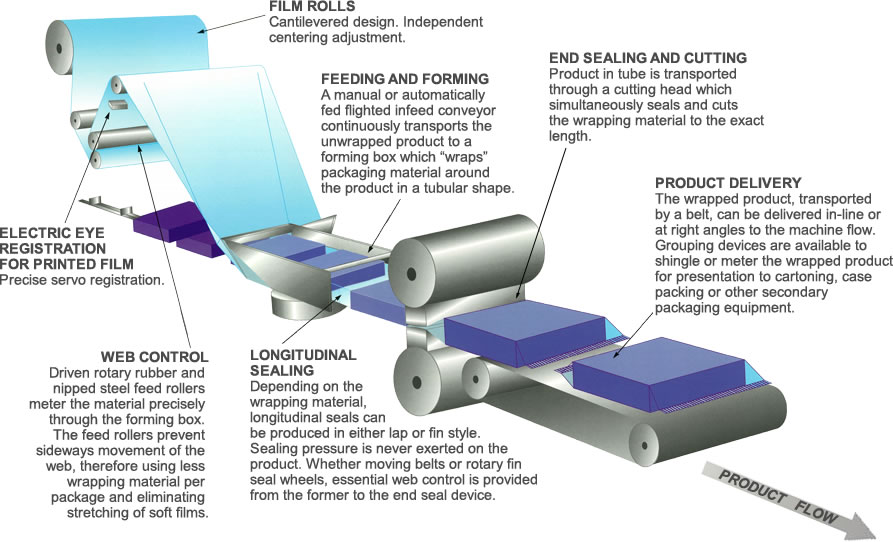

Products ranging from food and consumer products to medical devices travel horizontally in a continuous motion throughout a flow wrapper. Products are either manually or automatically placed onto an infeed conveyor which transports the product to the former. A single layer of wrapping material is fed into the machine and the former guides the material to create a tubular shape around the product. After the product has traveled through the former, the two edges of the packaging material are joined together under the center of the product. The joined edges of the material are then sealed together in either a longitudinal fin or a lap style seal. After the longitudinal seal is formed, the product is transported through rotary sealing/cutting jaws. As the cutting head rotates it simultaneously seals and cuts the front of one package and the back end of another. The finished package is then discharged from the sealing/cutting head area by a conveyor belt. The discharge conveyor carries the finished package away from the sealing and cutting area for integration with cartoners, case packers or other secondary packaging equipment.